You are here: Panda Wiki>EMC Web>ForwardEndcapMeetings>Minutes2014-09-29 (2014-09-30, FritzHerbertHeinsius)Edit Attach

Minutes of the forward endcap EMC meeting, 29th of September 2014, SeeVogh, 14:00 - 16:20

Topics are not in the order of discussion but by subject. Presence- Basel: excused

- Bochum: Claudius, Fritz-Herbert, Malte, Matthias, Tom

- Bonn: Christoph

- Groningen: excused

- Orsay: Philippe

- Uppsala: Pawel (via phone)

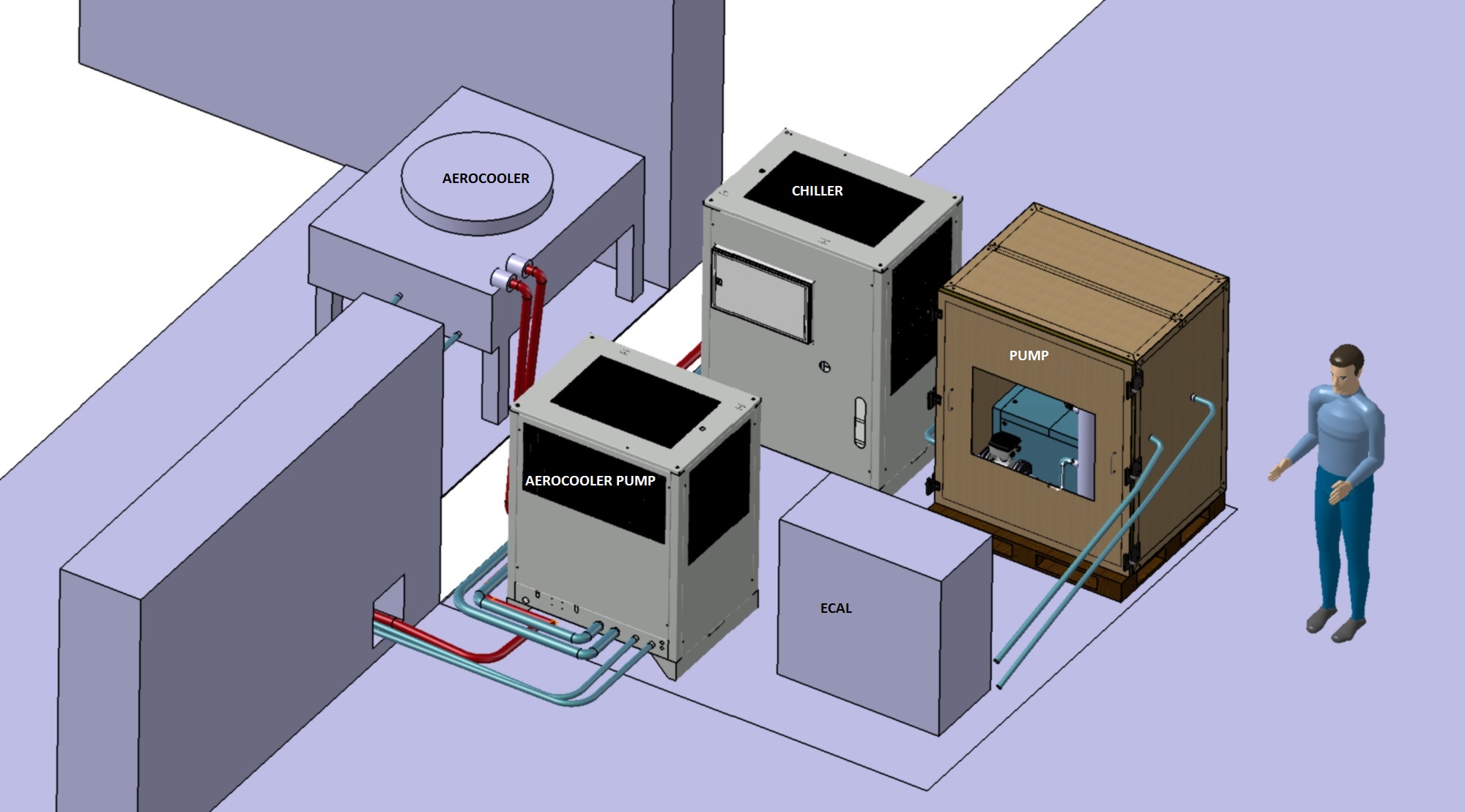

- 3D layout of cooling machine:

- Schematic of the cooling circuit

- ADC: Pawel: work on the user interface of the ADC is in progress. The next version of the ADC is envisaged to be ready by Christmas.

- Shaper: Christoph: the layout of the external shaper (for test purposes) is done. The shaper, with shaping according to the final ADC design, should be ready in 3 weeks.

- ADC crate: It is not clear how the ADC crates will be arranged in detail. It was discussed how to connect the signal cables. The best solution would be a backplane through which power is distributed and signal cables are connected. Space is tight. To save space Pawel suggested to move the DC/DC converters from the ADC to a common power supply (in each crate). Thus the ADC PCB can be shorter. Layout of the ADC crates should be done in a way, that one can remove ADC without disconnecting cables etc.

- Signals to ADCs: Signal cables are lay out in groups of 16 from each alveole. 16pin connectors are used. Each high rate VPTT alveoli can be put together with one half low rate APD alveoli on one ADC (total 32 ch. each high and low gain). Action: Ask Myroslav for rate estimates and if the FPGAs will handle these rates. Different distributions could be done through the backplane, but would be complicated and increase noise/crosstalk.

- Question: Will we use one or two SFP fibre connectors (redundancy)?

- Signal cables: estimates are ok. Cables can be ordered.

- Flat cables to THMP: cables can be ordered.

- HV connectors: Molex connectors need about 20min to mount. Buy connectors.

- HV cables: Will use cables from alveole PCB in cold area up to patch panel in crate outside magnet. Claudius will ask Lars/Jost for crate position and 3D model of magnet etc. to improve length estimate. After that cables can be ordered.

- HV connectors to iseg modules: Use thin or standard HV cables from patch panel to HV modules? HV has SHV connectors. Question: could we use Riedel connectors, which better fit thin HV cables?

- Backplate frame is set up at Bochum in target lab. The endcap backplate with stiffener ring will be mounted soon.

- Do paper box models for crates, THMP and LP to test mounting in backplate (Malte).

- Bonn is waiting for the interface piece design from KVI-CART (angles and manipulator holes).

- Increase hole for LP to M2 in mountplate.

| I | Attachment | Action | Size | Date | Who | Comment |

|---|---|---|---|---|---|---|

| |

Plan_Salle.jpg | manage | 241 K | 2014-09-30 - 17:55 | FritzHerbertHeinsius | 3D layout of cooling machine |

| |

etude.pptx.pdf | manage | 42 K | 2014-09-30 - 17:58 | FritzHerbertHeinsius | Schematic cooling machine |

Edit | Attach | Print version | History: r1 | Backlinks | View wiki text | Edit wiki text | More topic actions

Topic revision: r1 - 2014-09-30, FritzHerbertHeinsius

EMC Web

Web Home | Search Changes | Notifications Index | Topics

Web Home | Search Changes | Notifications Index | Topics

- Webs

- Cerenkov * Cerenkov.Pandacerenkov * DCS * Daq * Daq.Pandadaq * Detector * EMC * EMPAnalysis * Forwardstraws * GEM * MC * Magnet * Main * Mvd * PANDAMainz * PWA * Pbook * Personalpages * Physics * Physics.Baryons * Physics.CharmoniumAndExotics * Physics.HadronsInNuclei * Physics.OpenCharm * PhysicsCmt * SPC * STT * Sandbox * ScrutinyGroup * Tagpid * Tagpid.Pandatagpid * Tagtrk * Tagtrk.Pandatagtrk * Target * Target.ClusterJetTarget * Tof * WebServices * YoungScientists * ZArchives

Create personal sidebar

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Ideas, requests, problems regarding Panda Wiki Send feedback | Imprint | Privacy Policy (in German)

Ideas, requests, problems regarding Panda Wiki Send feedback | Imprint | Privacy Policy (in German)